Services

Cleaning & Recovery

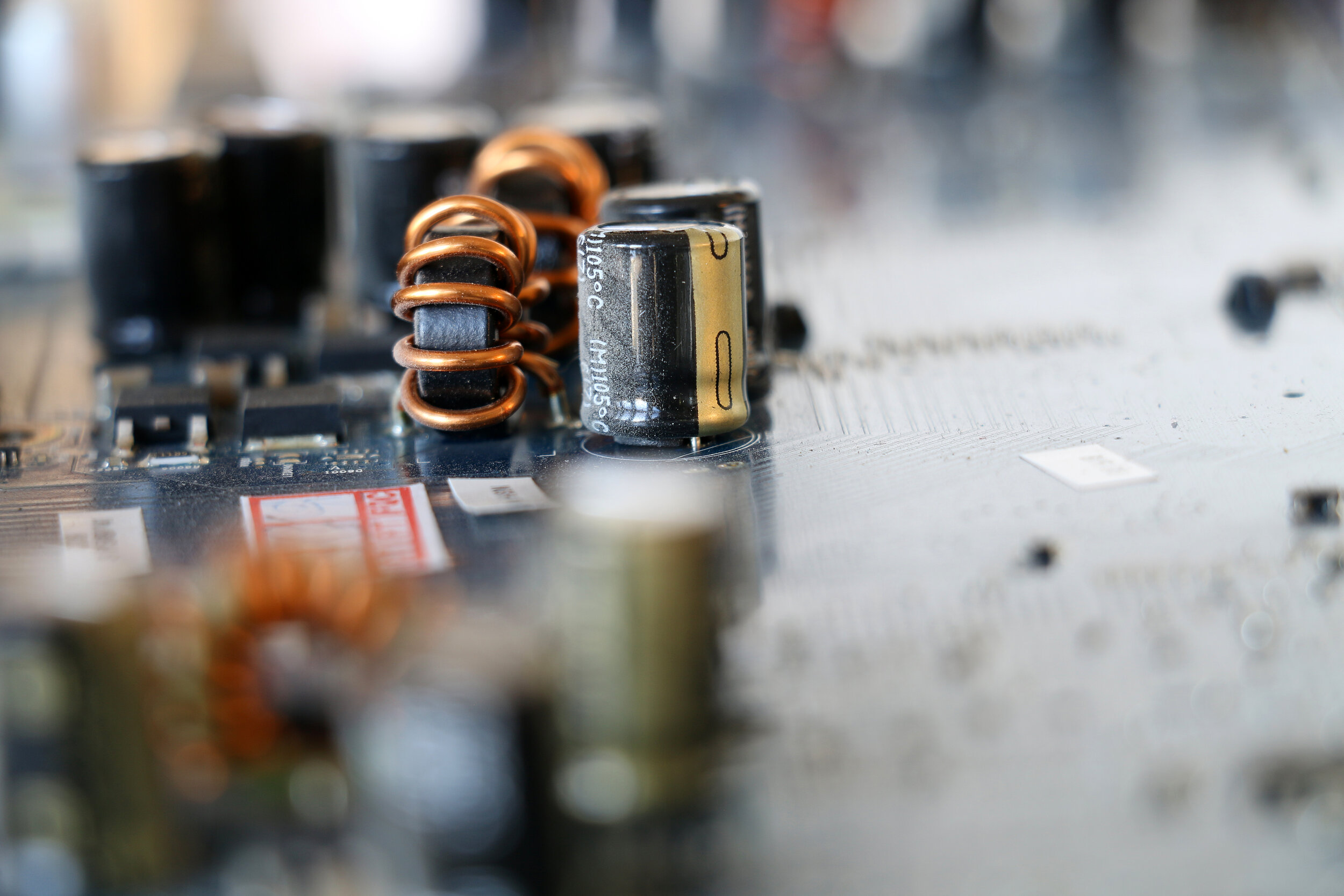

A clean batch of electronics is a safe, high-functioning batch of electronics. Recover parts or assemblies that were processed incorrectly and get to your peak performance.

Cleaning & Recovery

Cleaning of Electronics Assemblies and Components →

Assess cleanliness level, select/develop cleaning protocol and method, clean and verify.

Used to clean rework soldering fluxes or recover product that has been exposed to contaminants.

Used to recover product after contamination by a flood, fire or other residue-depositing situation.

Generally used when clients use no-clean fluxes or need alternative means of cleaning.

An investigation that establishes the incoming cleanliness level of the assessed product. Also used to verify the effectiveness of any selected Foresite cleaning method/protocol.

Increases the solderability of specified locations while maintaining the integrity of other areas.

Selective removal of coatings that contribute to failures when they react with ionic contamination.

Have questions about working with Foresite? Review our Standard Project Information or contact us.

They made it to a 99.4% yield increase.

Cleaning your PCBs can make a huge difference not just in the smooth functioning, but ultimately, the success of your products. One Foresite customer—a U.S. Automotive Supplier—reported, “The cleaning of the PCBs was successful and appreciated. [Team member] managed the project and reported a 3-4% yield increase, 97% to 99.4% yield increase. This is a big improvement.”

We’re proud to support businesses around the world with cleaning and recovery. If you’d like to read this and other case studies of how Foresite helped businesses deliver functioning electronics, check out our resources.